Dissolving Microneedles

Microneedles are an innovative drug delivery method that offers a painless, minimally invasive alternative to traditional injections. These tiny needles penetrate the skin’s surface to deliver medications or vaccines directly into the skin, without the discomfort of conventional needles. Microneedles are transforming the way drugs, vaccines, and even cosmetic treatments are administered.

Dissolving microneedles, made from biodegradable materials which dissolve after use, releasing the drug and eliminating sharp waste disposal. They reduce the risk of infections, provide precise dosage control, and improve patient compliance. Their safety and convenience make them ideal for a wide range of applications, from cosmetic uses to vaccines administration.

WCC's Dissolving Microneedles Mechanism

WCC's Dissolving Microneedles Key Advantages

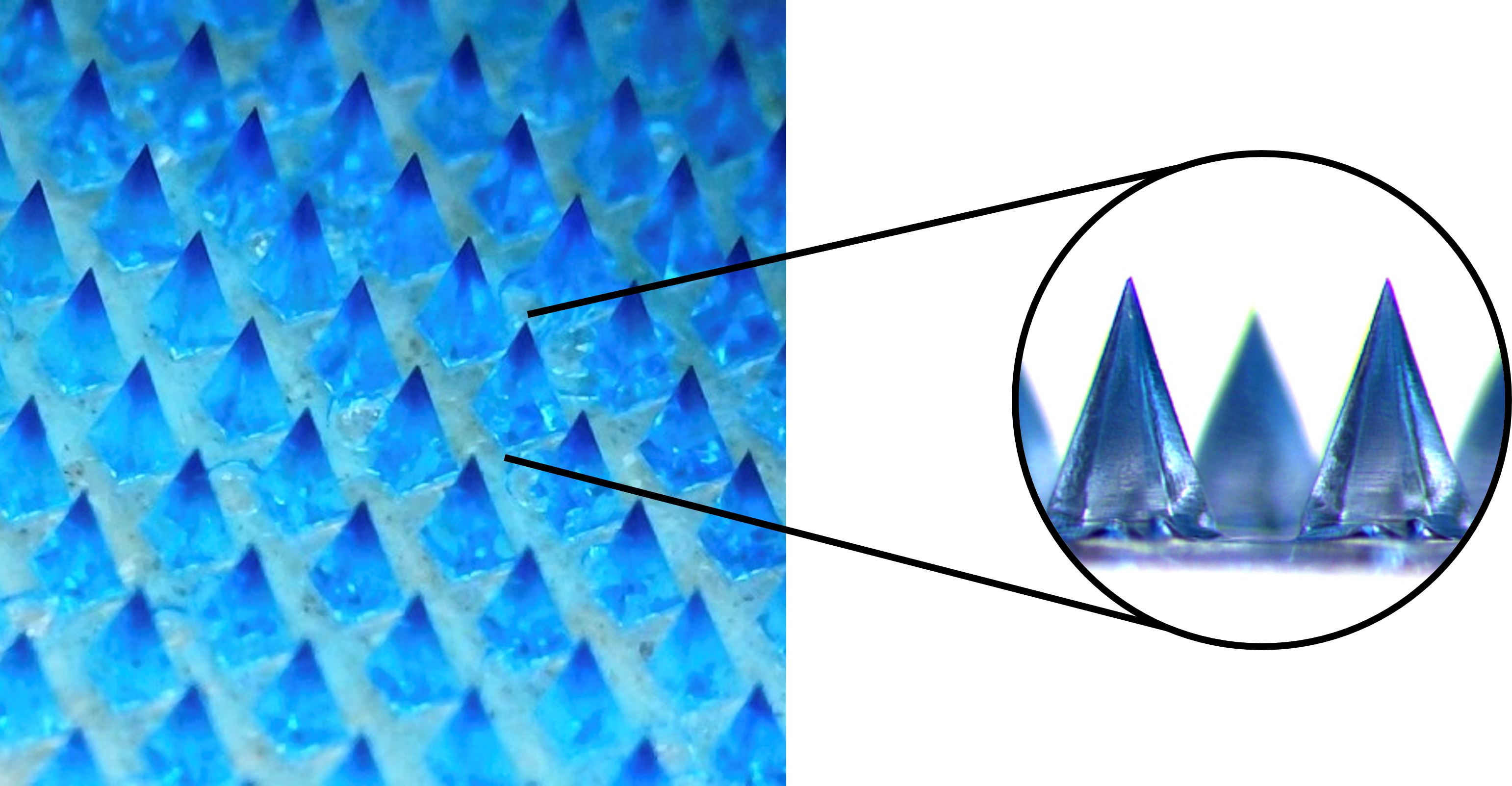

Among the various producers of dissolving microneedles, WCC Biomedical stands out with its highly specialized and advanced technology. What makes WCC Biomedical’s dissolving microneedles unique is their globally patented multi-layer structure, which is designed to enhance the precision and efficiency of drug and vaccine delivery.

The key innovation lies in the multi-layered design of the microneedles. Unlike conventional dissolving microneedles, WCC Biomedical’s microneedles incorporate the active pharmaceutical ingredients (APIs), such as drugs or vaccines, directly into the tip of the microneedles. This strategic placement ensures that the therapeutic agents are delivered accurately to skin, minimizing wastage and enhancing bioavailability. By concentrating the active ingredients in the tip, WCC Biomedical ensures highly targeted and controlled release upon administration. This technology is ideal for delivering sensitive biologics like vaccines, as well as small molecule drugs, ensuring that the correct dose is released exactly where it is most effective.

All of WCC Biomedical’s multi-layer structure microneedles are produced using their innovative platform, WINMAPᵀᴹ. WINMAPᵀᴹ is a fully integrated solution that streamlines the entire production process, from formulation and material selection to the automated mass production of microneedle patches. This platform enables high-quality, scalable production of dissolving microneedles, ensuring consistency and efficiency at every stage. Click here to know more about WINMAPᵀᴹ.