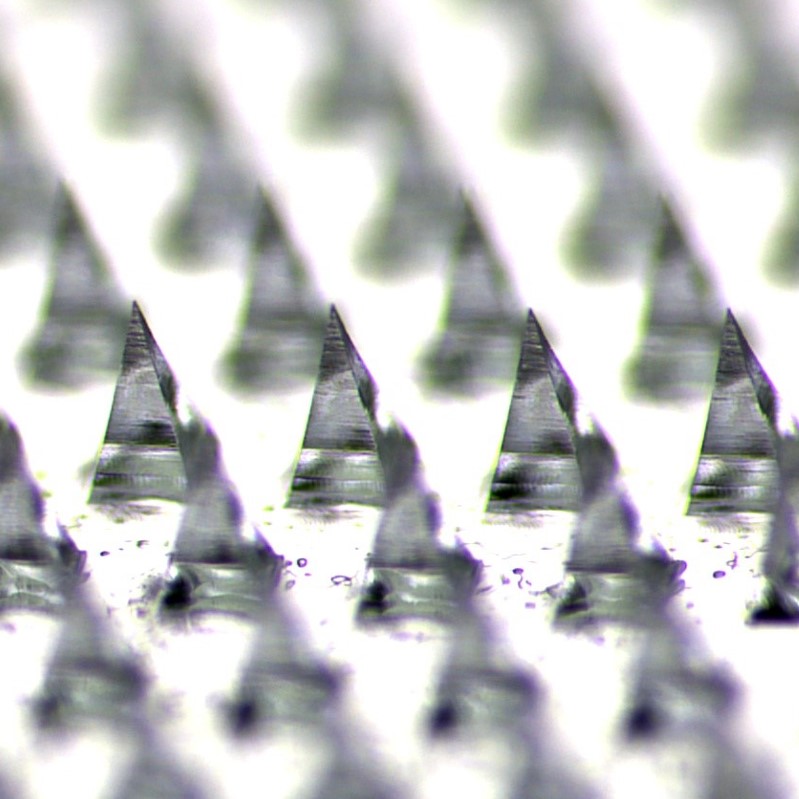

WCC Biomedical is a leading microneedle producer based in Taiwan. As the only Taiwanese company recognized by PATH, WCC stands out for its innovative 3-layer microneedles structure which patented globally for delivering drugs with precision, incorporating the active ingredients at tip of microneedle. The company’s dissolving microneedles are developed using its proprietary platform, WINMAPᵀᴹ, which ensures reliable and efficient drug delivery. This technology positions WCC at the forefront of microneedle advancements, offering cutting-edge solutions to healthcare challenges. Additionally, we have the capabilities for automatic mass production, ensuring efficiency and scalability in manufacturing.